If your business constantly scrambles to keep up with customer demand or sits on a mountain of unused stock, you’re not alone and not planning effectively. In today’s data-driven world, understanding demand vs. supply planning isn’t just helpful; it’s essential. Whether in retail, manufacturing, logistics, or even just trying to get your online orders out on time, balancing what your customers want with what you can deliver is the secret sauce to running a smooth, profitable operation.

Key Takeaways

- Demand planning forecasts customer needs using data, trends and seasonality.

- Supply planning ensures the right resources and stock are available to meet demand.

- Combining both enables smoother operations, happier customers and fewer stock headaches.

- Modern planning tools can turn messy spreadsheets into actionable insights.

- A strong planning partner (with brains, not just buzzwords) makes all the difference.

What Is Demand vs Supply Planning?

Let’s break it down like a good Aussie footy match — you need both offence and defence.

- Demand Planning is about predicting what your customers will want and when. It’s grounded in historical sales data, market trends, promotions, and external factors like weather or economic shifts.

- Supply Planning kicks in once you know what demand looks like. It’s the logistics of ensuring you’ve got the right products in the right place and time, without turning your warehouse into a hoarder’s paradise.

While demand planning is more customer-facing, supply planning is inward-facing, focused on your business’s ability to deliver.

Why Both Matter for Aussie Businesses

We’re not just talking about multinational giants here. Whether managing a warehouse in Wagga Wagga or running a supply chain in Sydney, having a clear picture of demand and a reliable plan is business-critical.

- Customer Satisfaction: If products aren’t available when customers want them, they’ll take their dollars elsewhere faster than you can say “backorder.”

- Cost Efficiency: Overstocking ties up capital, and understocking results in lost sales. Planning helps you avoid both.

- Operational Stability: A solid plan reduces firefighting and last-minute freight charges (as fun as a flat tyre in the outback).

- Data-Driven Decisions: No more gut feelings. You’ll be making calls backed by real, actionable data.

Common Challenges and How to Tackle Them

Here comes the fun part — the hurdles every planner secretly (or not-so-secretly) groans about. Here’s a listicle to make it feel less painful:

- Inaccurate Forecasts

Blame it on outdated data or poor historical records — but remember, bad data = bad planning. - Siloed Teams

Sales doesn’t talk to operations, finance is doing their own thing, and no one knows what marketing’s up to. Sound familiar? - Outdated Tools

If you’re still running forecasts on Excel sheets from 2012, it’s probably time for an upgrade. - Unpredictable Markets

Whether it’s COVID, climate change, or economic swings, volatility is the new normal. - Lack of Agility

You’ve got a plan, but it’s rigid. When something changes (and it will), everything falls apart.

Best Practices for Integrated Planning

Good planning isn’t magic — but it’s close. And like any good magic trick, it’s all about the setup.

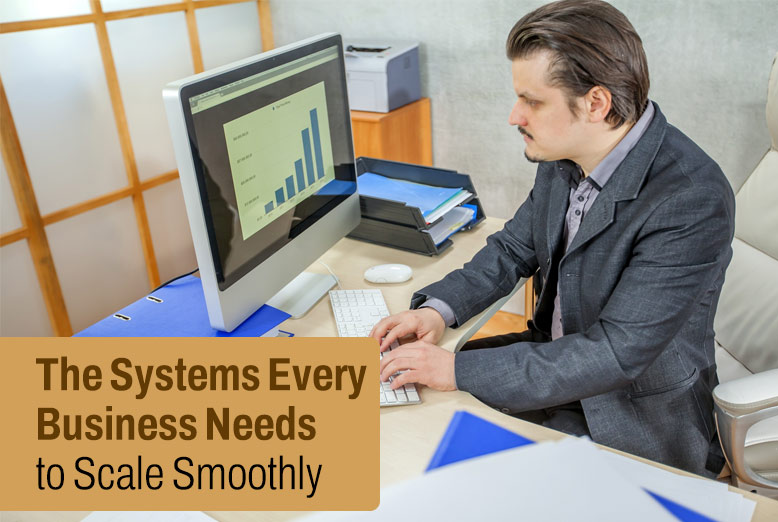

- Invest in the Right Tech: Tools like Anaplan or IBM Planning Analytics allow you to model, forecast, and simulate scenarios in real-time.

- Foster Collaboration: Align your departments. Sales, finance, and operations should all sit at the planning table.

- Use Both Historical and Real-Time Data: Past performance is functional, but live data (like POS or website traffic) brings your forecasts into the now.

- Plan for Variability: Build contingency plans. Your plan should bend, not break.

- Review and Refine: Demand and supply planning isn’t a one-and-done deal. Review your forecasts regularly and adjust based on what’s working (or not).

Why Work with Experts Like Tridant?

Let’s be honest: no business has time to become an expert in forecasting, planning software, and supply optimisation. That’s where the pros come in.

Tridant helps Australian businesses eliminate guesswork in planning by delivering end-to-end solutions for demand and supply. Whether it’s tool selection, implementation, or strategic advice, they work across industries to make planning actually work.

From integrating Anaplan or IBM Planning Analytics to ensuring your team isn’t lost in a forest of spreadsheets, they help you build smarter, scalable systems that grow with your business.

Conclusion

Understanding demand and supply planning is like knowing the difference between the brakes and the accelerator — you need both to drive your business forward without crashing. When done well, these practices reduce risk, increase profitability, and help your business stay agile in a world that refuses to sit still.

Want to get your planning strategy out of the too-hard basket? Get started with the consultants at Tridant and start making smarter, more confident decisions today.

Also Read: The Digital Twin Supply Chain: Why ELT Conquers Real-Time Logistics Optimization